BIM reaches small to medium-sized enterprises

Haas & Haas GmbH believes that the future exists in a combination of traditional values and modern technologies: Investing in innovative processes is important for SMEs so that they can continue to be successful in future.This family-owned company based in Lichtenau am Oberrhein in Baden-Wuerttemberg, Germany, was founded in 1980 by Robert Haas and now has more than 50 employees. His son, Jan Haas, started working at the company as Joint Managing Director in 2012.

Jan Haas has long recognised the potential of digitalisation for his company: "In order to retain the loyalty of our many excellent employees in future, we need to remain competitive and streamline workflows with the help of digital solutions", he explains. After all, although the construction sector is often still critical of digital change, digitalisation now influences all economic sectors and a large part of the value chain.

Profiting from digitalisation

Numerous digital applications and software solutions already exist in the construction sector, such as in the area of procurement and construction site logistics. At Haas+Haas, the use of software for formwork planning has proven to be a great success during work preparations. "It is important for us to be able to use our materials efficiently and deliver exactly the right formwork material to the construction site", clarified Jan Haas when asked why he uses formwork software at the company.

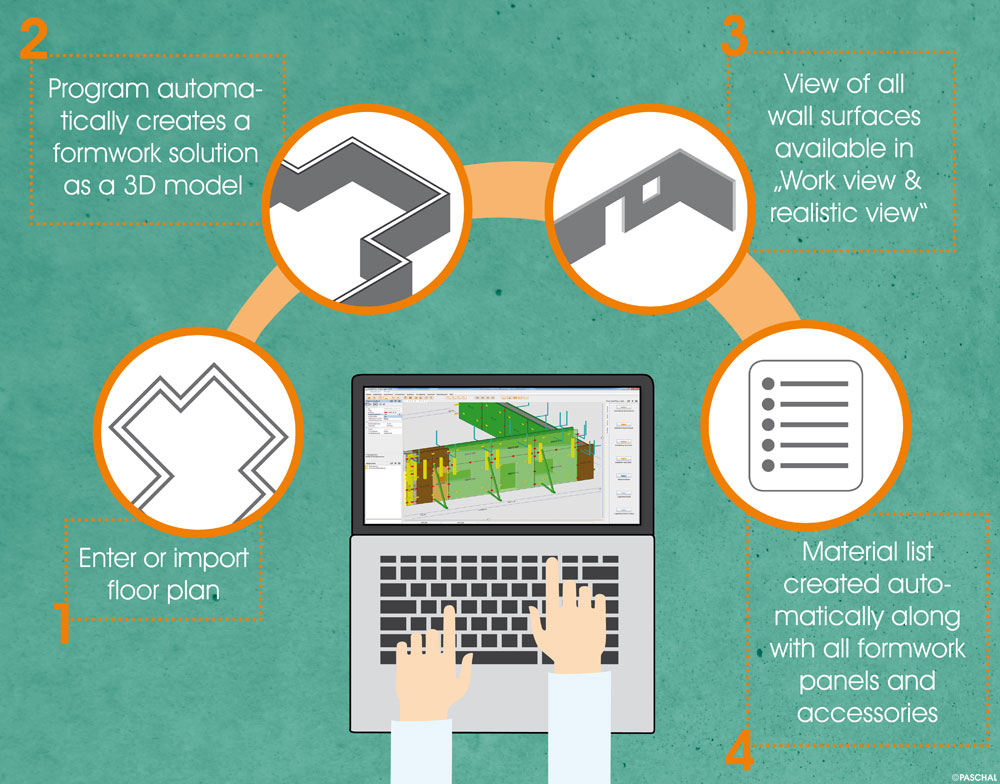

Haas+Haas GmbH has been using PPL formwork software from PASCHAL/planitec since 2015. The user can enter floor plans or import existing drawings in PPL to create formwork plans. The program then automatically creates a formwork solution in the form of a 3D model. The user can create sections and views of all wall surfaces in the desired display depth.

At Haas+Haas, drawings produced by PPL have already been in effective use for some time: "We come back to the formwork plans to discuss important details, such as the phases, with the foreman in the office. This allows us to clarify any ambiguities in advance, which is far more effective than having to deal with questions once our materials have already reached the construction site", explains Jan Haas.

Work preparation with PPL 11.0 from PASCHAL/planitec

In addition to the formwork planning, the software automatically generates a corresponding material list which lists all formwork panels in the required quantities along with all the necessary accessories. In addition, the "Warehouse" module in PPL 11.0 allows the user to dynamically query the material in the warehouse. This means that not only is the current inventory recorded, but all the inventory movements as well. For instance, if material is returned to the warehouse during the project, the formwork plans can be automatically adapted to the formwork material we currently have available. "Using "Warehouse" allows us to use our formwork in an optimal way and immediately see what material is available in the warehouse. If shortages occur, we can immediately ask the formwork manufacturer to supply us with a quotation for the formwork material needed to be hired via the shortages list", explains Jan Haas. To summarise, work preparation is clearly rationalised, the efficiency of individual work processes is increased and the costs for unnecessary material storage on the construction site and transport are minimised.

USER BENEFITS

- Enter a floor plan or import it via the DXF, DWG or IFC interface and automatically create 2D and 3D formwork plans

- The complete material list is generated automatically along with the formwork plans.

- Formwork plans optimised according to availability with "Warehouse" (PPL 11.0)

Building Information Modelling is also important for small to medium-sized enterprises

The example of Haas & Haas GmbH makes it quite clear that software solutions for digital construction and planning are of fundamental importance to medium-sized enterprises today, and that digitalised business processes will play an increasingly important role.

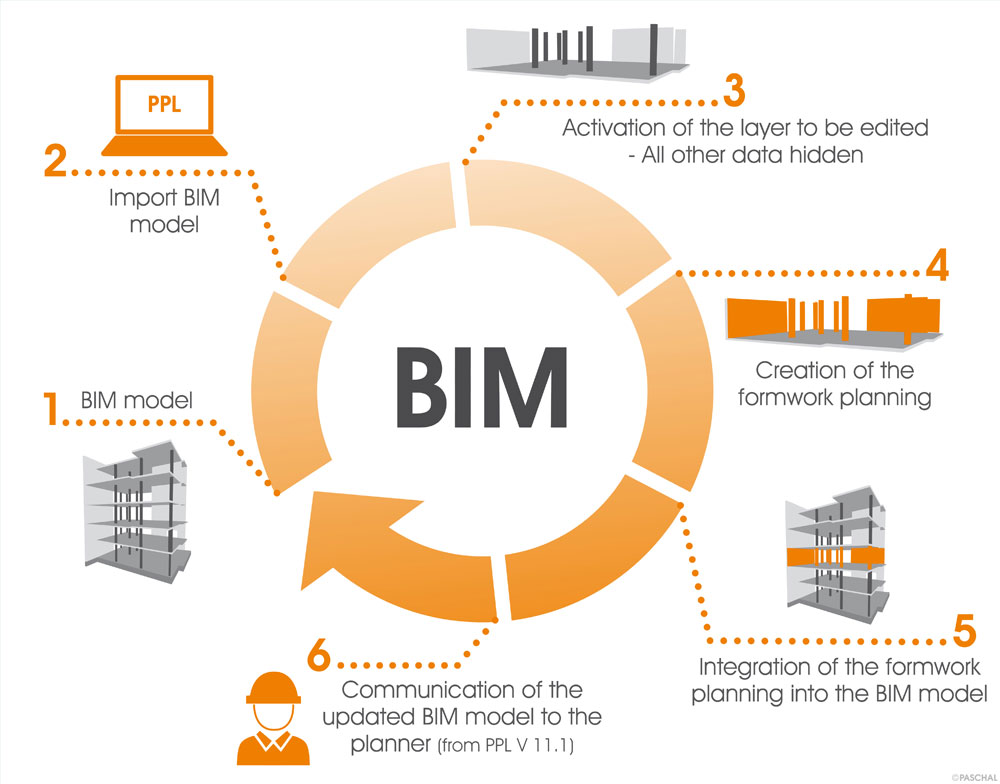

In the construction sector, digitalisation with BIM (Building Information Modelling) has made a name for itself. The aim of BIM is to ensure the continuous exchange of building data models via software interfaces (IFC) between all sections involved in a project over the complete life-cycle of a building. There is still a long way to go until BIM is fully introduced, but partial solutions limited to individual companies in a project are already working successfully. And this is where the digital strategy at Haas+Haas comes into its own: "For us, working with formwork software and the corresponding exchange with the planner and formwork manufacturer already represents an important step in the direction of BIM", states Jan Haas. In order to be able to benefit at an early stage from BIM, Haas+Haas intends to utilise additional BIM-capable software in the future. Jan Haas is certain of one thing: "The digital transformation at small to medium-sized construction companies can only come to fruition if mobile devices become standard equipment on the construction site." To underpin this, he plans to send formwork plans and 3D models directly to the foremen on the construction site by introducing sturdy tablets and the BIM-capable PPL 11.0.

BIM-capable software and mobile devices will make 3D models directly available on the construction site