Aim high – That’s for sure!

Efficient and swift concreting with the PASCHAL Climbing system 240An observation tower in a treetop path, a water tower in the Eifel mountain range or the largest timber house in Denmark: in many cases, builders want to aim high. And this works better by combining formwork and the Climbing system 240. To demonstrate this, we'll take you on a trip from a Danish Baltic Sea island to the Swiss border and visit special construction projects. They all have one thing in common: Together with the Climbing system 240, PASCHAL formwork 'grew' upwards and shortened the concreting times of towers, tall buildings and elevator shafts.

We travel from the island of Funen in Denmark to Lörrach am Rhein, stopping at Lüneburg Heath, the Eifel mountain range on the border with Belgium, before heading to the Grand Est region of France and then reaching the border town with Switzerland. This is because PASCHAL formwork solutions are used universally in construction projects – be it a government building, an observation tower, a water tower, an exposed concrete tower or a hotel tower: always in combination with the 240 Climbing system. No matter how different the dimensions and structural conditions were – whether a round tower or a square elevator shaft: the construction companies carrying out the project opted for PASCHAL climbing formwork in order to pour concrete quickly and work economically.

General contractor NCC used PASCHAL climbing formwork for the stairwells and elevator shafts for the new WoodHub government building on the island of Funen. Denmark's tallest timber house will open in 2025.

Concrete elevator shafts stabilise Denmark's largest timber house

In the case of WoodHub – the future government building in Odense – the formwork for the elevator shafts grew upwards floor by floor together with the climbing bracket 240. Because, even if you don't see it from the outside of the sustainable building: The timber structure – which extends over a total area of 31,000 m² over 7 floors, requires concrete on the inside as a stabilising material. A total of six concrete stairwells and elevator shafts support the WoodHub. NCC Danmark acted as general contractor for the project. WoodHub is being built according to plans designed by the well-known architectural office CF Møller Architects at a total budget of €86.5 million and will open in 2025.

The observation tower in the Heide Himmel treetop path in Lüneburg Heath was completed in a total of 14 cycles. The Wall formwork LOGO.3 in combination with the Climbing system 240 was used to form the climbing formwork for the shaft.

Once pre-assembled – it just takes a few crane lifts

There is a square elevator shaft and observation tower approximately 300 kilometres as the crow flies south of the island of Funen, in the Lüneburg Heath Wildlife Park located in central Lower Saxony. From its observation platform at 44 metres, you can not only look down onto the Heide Himmel treetop path, but also have a panoramic view as far as Hamburg. The Wall formwork LOGO.3 in combination with the Climbing system 240 was used to form the climbing formwork for the shaft. The climbing unit – consisting of the vertical formwork unit and three platforms along with protective scaffolding – was pre-assembled only once and lifted with one crane lift for the following concreting cycle. Two concreting cycles were carried out per week; the observation tower was completed in a total of 14 cycles. Approximately 1,000 m³ of concrete, 130 t of reinforcing steel, 600 t of steel, 350 m³ of timber and 70,000 screws were used. Now, let's say goodbye to the lynx, otters and wild boar, and drive 640 km further southwest to the Eifel National Park near the Belgian border.

Climbing platform with enough space to work

The Eifel mountain range is located on volcanic rock and is therefore an earthquake zone. In order to make the bottom outlet tower at the Urft Dam – one of the oldest dams in Europe – earthquake-proof, it was renovated last autumn and provided with a concrete casing. PASCHAL's Circular Trapezoidal girder formwork (TTR) was used to form the tower in seven cycles. The climbing platform served as a working and protective scaffold for the employees of the construction company Bruno Klein. The special feature of this project: The climbing unit could not be moved in its entirety by crane as the diameter of the custom-made formwork was only 3.80 metres and involved working in a confined space as well as the impassable terrain surrounding it due to the water tower standing next to the dam wall on a steep slope. Foreman Martin Ketterer – who has been managing formwork projects at PASCHAL for 28 years – explains: 'Strictly speaking, it was not a climbing formwork as the formwork and climbing platforms moved upwards separately. Between cycles, the formwork was placed on the ground and cleaned.'

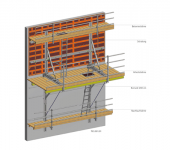

This is different in the 'real' climbing unit. By the way, the number 240 stands for the depth of the platform. This leaves enough space for the push-pull props that reinforce the formwork. In addition, the formwork can be retracted by up to 70 centimetres. This allows it to be cleaned on site before the next cycle. Hans-Peter Steiner, head of technical documentation and training manager at PASCHAL: 'The climbing platform has a maximum load of 3.0 kN/m2. This means that up to four people can stand in one square metre. There is also space on the platform to store tools and small equipment.' Conclusion: The Climbing system 240 is designed to increase work safety and simplify the formwork's operability.

Now, we head towards Strasbourg, cross the border to France and stop in the twin town of Cernay-Wittelsheim in the Grand Est region.

Exact formwork planning = shorter construction time

The construction company Scherberich S.A. formed the 25-meter-high exposed concrete tower of the emergency centre in Cernay-Wittelsheim in eight concreting cycles – without having to rebuild the formwork unit. This consisted of the Wall formwork LOGO.3, the working platform, the concreting platform and the suspended scaffold. The construction team was under time pressure. One concreting section needed to be completed every three days. And thanks to perfect work preparation, this was also achieved, confirms Christian Houvig, construction manager at Scherberich S.A. He said: 'With the five formwork units – one internal shaft unit and four external units – we were able to meet the construction deadlines for the reinforced concrete tower thanks to PASCHAL's precision preliminary planning, and we didn't have to make any on-site formwork modifications'.

For increased occupational safety: Small anchor, big impact

The Climbing system 240 in the project in France as well as in the tower of the Heide Himmel treetop path was anchored with the anchor cone M30/DW15. This building-authority-approved anchor cone simplifies and speeds up the anchoring of the climbing system; it has been developed to be suitable for all climbing and platform systems. To construct the reinforced concrete tower of the rescue centre, only two horizontal anchoring points were required externally per concreting cycle in order to attach a complete formwork unit to each side of the tower. The anchor cone is approved for anchoring depths of 250 to 400 mm as a normal wall anchoring. Particularly sustainable details: The anchor consists of three components, only two of which remain in the concrete. The cone is reusable!

Individual adaptations for special challenges

Flexibility is key – this is the motto that PASCHAL's formwork planners follow in order to plan the formwork individually for each construction project; their focus is always on ensuring that the construction company is able to achieve as many of the desired formwork heights and diameters as possible with as little use of materials as possible in as few concreting cycles as possible. The Formwork Technology project team is always coming up with new ideas. One of their special projects was the tower of a 4-star hotel in Lörrach, not far from the Swiss border. This brings us to the end of our journey as we shed light on the challenges that were overcome in this construction project. A special climbing concept was created for the new hotel building opposite the main train station that combined the Climbing system 240 with the formwork system LOGO.3. The formwork was, therefore, implemented up to a height of 63 meters over 20 floors. However, the construction company Implenia Bau wanted the climbing platforms to move up from floor to floor with as few crane lifts as possible. In order to achieve this, two climbing platform sizes were combined and the crane lifts were optimised. This meant that there were four climbing platforms on each side of the tower, each approximately six metres long. A special beam was constructed to safely transfer the horizontal forces from the climbing platforms to the remaining reinforced concrete walls and pillars.

For the new hotel building in Lörrach, the corner solutions of the climbing formwork were planned so that the workers can move safely even at a height of 63 meters.

Safe working even on the 40th floor or despite the sloping wall

The Climbing system 240 ensures that employees have enough space to do their work safely. It is important that workers can work safely at any height, not only in tall buildings such as the hotel tower in Lörrach. As an additional safety measure, the corner solutions were planned so that workers can move safely around the corners. PASCHAL's formwork planners planned the climbing unit in the outdoor area so that the working platform, concreting platform and finishing platform are flush with the edge of the building from one side. On the other side, the platforms were extended to ensure a sufficiently wide overlap. Even sloping walls are no obstacle. If an architect wishes to build using non-conventional angles, the climbing system adapts to the building geometry: this is possible by up to +/- 15 degrees. This means: The work platform always has a horizontal position, even on inclined walls. This is due to the articulated fastening of the vertical beam to which the formwork is attached. This means that you're well equipped, even with slightly sloping walls.